1. Blanking

The factory selects different blanking methods according to the design development drawing. Weiyin Company basically adopts two methods: one is cutting and blanking, the other is CNC laser blanking;

2. Bending

The 2D flat parts are photographed into 3D parts, which are generally completed by the bending bed or corresponding bending mold. The picture shows our employees bending.

3. Welding

Multiple parts are welded together for processing purposes, or a single retail edge is welded to increase the strength of the parts. Weiyin usually adopts spot welding, argon arc welding and CO2 shielded welding.

4. Finishing

After blanking and welding of workpieces, corners, burrs and contact points shall be trimmed (polished) as necessary. At the tool contact point, the flat file shall be used for trimming. For workpieces with large burrs, the grinder shall be used for trimming, and the corresponding small file shall be used for trimming the small inner hole contact point to ensure the appearance is beautiful. At the same time, the trimming of the contour also ensures the positioning during bending, Make the position of the workpiece against the bending machine consistent when bending, and ensure the consistency of the size of the same batch of products.

5. Painting

Some workpieces have high requirements on the surface and need to be scraped before spraying; Some workpieces are protected by special high temperature resistant stickers at the grounding symbol. When spraying, first hang the workpiece on the assembly line and blow off the dust on the surface with a gas pipe. Enter the spraying area for spraying. After spraying, enter the drying area along the assembly line, and finally remove the sprayed workpiece from the assembly line.

6. Assembly

Combine multiple parts or components in a certain way to form a complete material. Before assembly, the protective stickers used in the original spraying shall be removed to ensure that the internal threaded holes of the parts have not been sprayed with paint or powder. During the whole process, gloves shall be worn to prevent dust on the hands from adhering to the workpiece, and some workpieces shall be blown clean with an air gun.

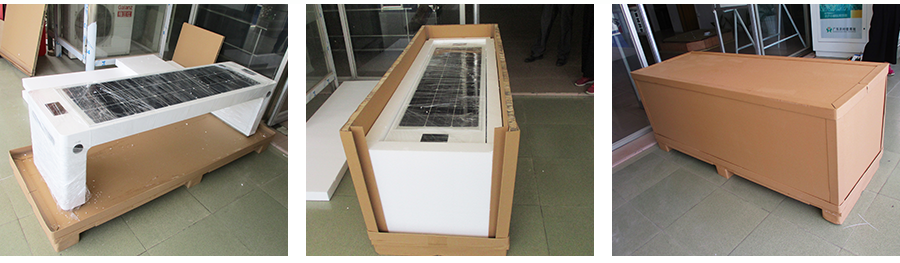

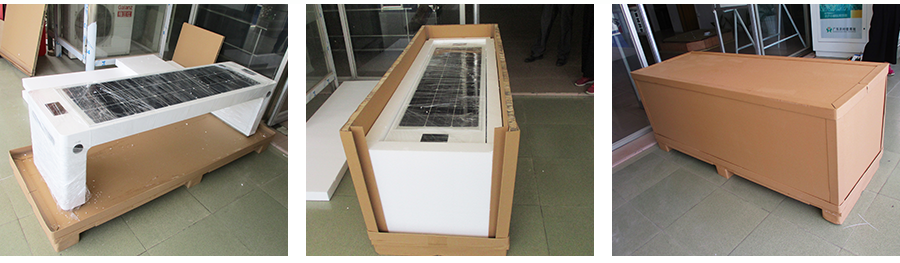

7. Packaging

After inspection, the workpieces shall be put into special packaging bags for protection. Some workpieces without special packaging shall be packed with bubble film, etc. Before packaging, the bubble film shall be cut to the size that can package the workpieces, so as not to affect the processing speed by cutting while packaging; Large quantities of special cartons or bubble bags, rubber pads, trays, wooden boxes, etc. can be customized. After packing, put it into the carton, and then stick the corresponding finished product or semi-finished product label on the carton.